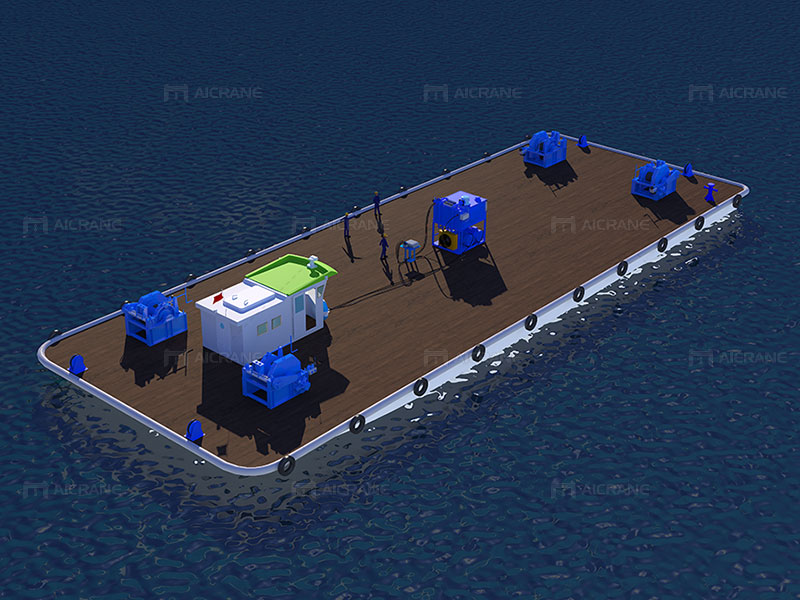

Deck winches play a crucial role in various maritime operations, offering efficient and reliable means for handling heavy loads. However, installing a deck winch requires careful planning and execution to ensure optimal functionality and safety. In this article, we provide a comprehensive deck winch installation outline, guiding you through each step of the process. By following this guide, you’ll be equipped with the knowledge and understanding necessary to install your deck winch successfully, ensuring smooth operations and peace of mind.

I. Pre-installation Considerations

Before diving into the installation process, several essential factors must be considered. First, determine the load requirements and assess the winch’s capacity to ensure it meets the intended application’s demands. Next, choose the appropriate deck winch type (electric, hydraulic, pneumatic) based on your specific needs. Additionally, ensure compliance with safety regulations and standards relevant to your industry. Finally, select the necessary winch components, such as wire rope, drum, and control system, that align with the requirements of your operation.

II. Deck Winch Installation Outline

A. Preparation Phase

Site assessment and planning: Evaluate the installation area, considering space, accessibility, and structural integrity. Plan the winch placement and take note of any potential obstacles or safety hazards.

Gathering necessary tools and equipment: Ensure you have all the tools and equipment required for the installation, such as wrenches, hoists, and rigging gear.

Ensuring proper safety measures: Implement necessary safety precautions, such as wearing appropriate personal protective equipment (PPE) and following lockout/tagout procedures.

B. Mounting and Positioning

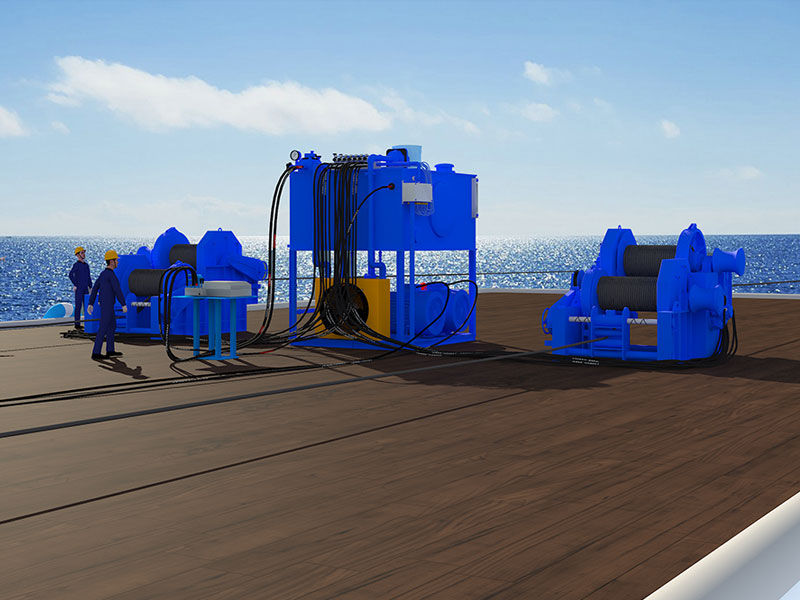

Identifying optimal marine winch location on the deck: Take into account factors like load distribution, operational convenience, and space constraints when selecting the ideal winch location.

Mounting brackets and anchor points: Securely attach the winch mounting brackets or base to the deck using appropriate fasteners. Ensure the anchor points are strong and properly aligned.

Alignment and leveling considerations: Verify that the winch is properly aligned with the intended load path and ensure it is level to prevent unnecessary strain on the winch components.

C. Power Supply and Electrical Connections

Determining power requirements and sourcing: Assess the power needs of the winch and ensure a suitable power source is available. Coordinate with electricians to connect the winch to the power supply.

Proper installation of electrical cables and connections: Follow manufacturer guidelines for wiring the winch, ensuring correct wire sizing, proper grounding, and secure connections. Adhere to electrical safety standards and local regulations.

Integration with power distribution systems: If applicable, connect the winch to the existing power distribution system on the vessel, ensuring compatibility and compliance with electrical codes.

D. Installation of Winch Components

Attaching the drum and spooling device: Securely mount the winch drum and ensure it rotates freely. Install the spooling device, such as a level wind system, to ensure even distribution of the wire rope or cable.

Installing wire rope or cable properly: Thread the wire rope or cable through the winch drum, ensuring it is properly wound and tensioned. Follow manufacturer instructions for correct spooling techniques.

Securing and adjusting tensioning mechanisms: Install any necessary tensioning mechanisms, such as wire rope clamps or tensioning systems, and adjust them to the recommended specifications for safe and efficient operation.

E. Control System and Operation

Installation of control panel or console: Mount the winch control panel or console in a convenient and accessible location for the operator.

Wiring and connection of control components: Connect the control panel to the winch, ensuring proper wiring and functionality of controls, switches, and indicators.

Testing and calibration of control system: Before putting the ship winch into service, conduct thorough testing and calibration of the control system to ensure smooth operation and accurate control of the winch.

F. Safety Measures and Inspections

Implementing safety features: Install essential safety features, such as emergency stop buttons, limit switches, and overload protection systems, to safeguard personnel and equipment during winch operation.

Conducting thorough inspections and load testing: Perform comprehensive inspections to verify the integrity and functionality of all winch components. Conduct load testing to ensure the winch operates within its specified limits.

Verification of proper functioning and compliance: Validate that the installed winch meets all relevant safety regulations, industry standards, and manufacturer guidelines before deploying it for operational use.

III. Maintenance and Troubleshooting

To ensure the longevity and optimal performance of your deck winch, it’s crucial to establish a regular maintenance routine. Follow manufacturer guidelines for routine maintenance practices, including lubrication, cleaning, and periodic inspections. Additionally, familiarize yourself with common winch issues and troubleshooting techniques to address any potential malfunctions promptly. Regularly inspect the winch for signs of wear, damage, or loose connections, and take corrective measures as needed.

Conclusion

By following this comprehensive deck winch installation outline, you can ensure a successful and safe installation process. Proper planning, attention to detail, and adherence to safety guidelines are vital for optimal winch performance and longevity. Remember to consult manufacturer guidelines and seek professional assistance whenever necessary. With a well-installed deck winch, you’ll have a reliable and efficient tool at your disposal for handling heavy loads in maritime operations.