Technology has paved the way for manufacturing a variety of stone crushers to perform this tedious task. Under normal circumstances, deforming rocks becomes a tedious process as it relies on the strength of the person working on it. The results achieved were contrary in a case where rock handled the force. However, working with stone crushers makes it more convenient and also timely. It is safe and saves on costs. One of such stone crushers is the impact crushers. It is an efficient model that deals mostly with aggregates to reduce them into considerable sizes.

Furthermore, they are versatile hence applicable in all levels of crushing without much interference on its performance. The kind of results achieved is even in all tasks. Impact crushers come in two designs; horizontal shaft(eje horizontal) impact crushers HSI and vertical shaft impact crushers VSI. The two work on the same principle to crush the rocks into refined products. However, they all have varying features, functionality levels and their optimal applications also differ. Nevertheless, you can find each of them in either a stationary or mobile design. The kind of demands you have at your project determines the type that you choose.

Vertical Shaft Impact Crushers

Vertical shaft impact crushers work on a method called the rock on rock. The device has a feeding feature where you have to put in the material. It is at the center of the rotor. In most cases, its operation is similar to that of a centrifugal pump. The rocks move to the crushing surface at high speed upon feeding, for continuous crushing until it gets to the desired size. There is a small opening at the periphery that lets out the stone once it gets to the required dimensions. In the crushing surface, the rocks collide against each other hence breakages. The colliding is efficient as the materials move while hitting the outer body, thus coming back in force to cause a more substantial impact. It is the speed and power that makes crushing possible in this device. With such a mechanism, the model is ideal for the last stages of aggregate production. You can use it in construction industries, grinding mills and mines(molinos y minas).

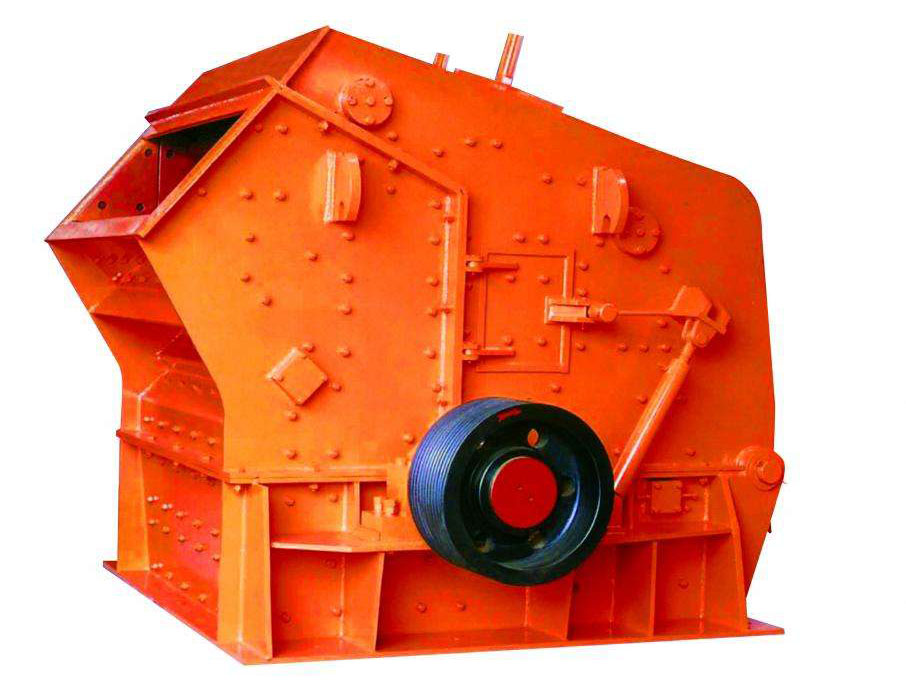

Horizontal Shaft Impact Crushers

Horizontal shaft impact crushers execute crushing through the aid of an impact produced through rotational movements. The device has a set of bars and hammers fitted on the rotor that moves at high speed, hence breaking down the materials in smaller portions. Upon feeding, the rock passes through this surface, and then once it breaks, it further moves to the next step for finer crushing. The fragmentation of the broken materials in the crushers then results in a more refined output. It is due to collision against each other and the walls of the chamber. The operator can control the dimensions of the work, depending on the operative needs. The HIS is suitable for primary, tertiary and secondary crushing stages. You can click this link for more info: http://aimixtrituradora.com/trituradora-de-impacto/

Both types of impact crusher’s further come in varying models suitable for all unique demands. However, all of them use impact as their base of crushing.